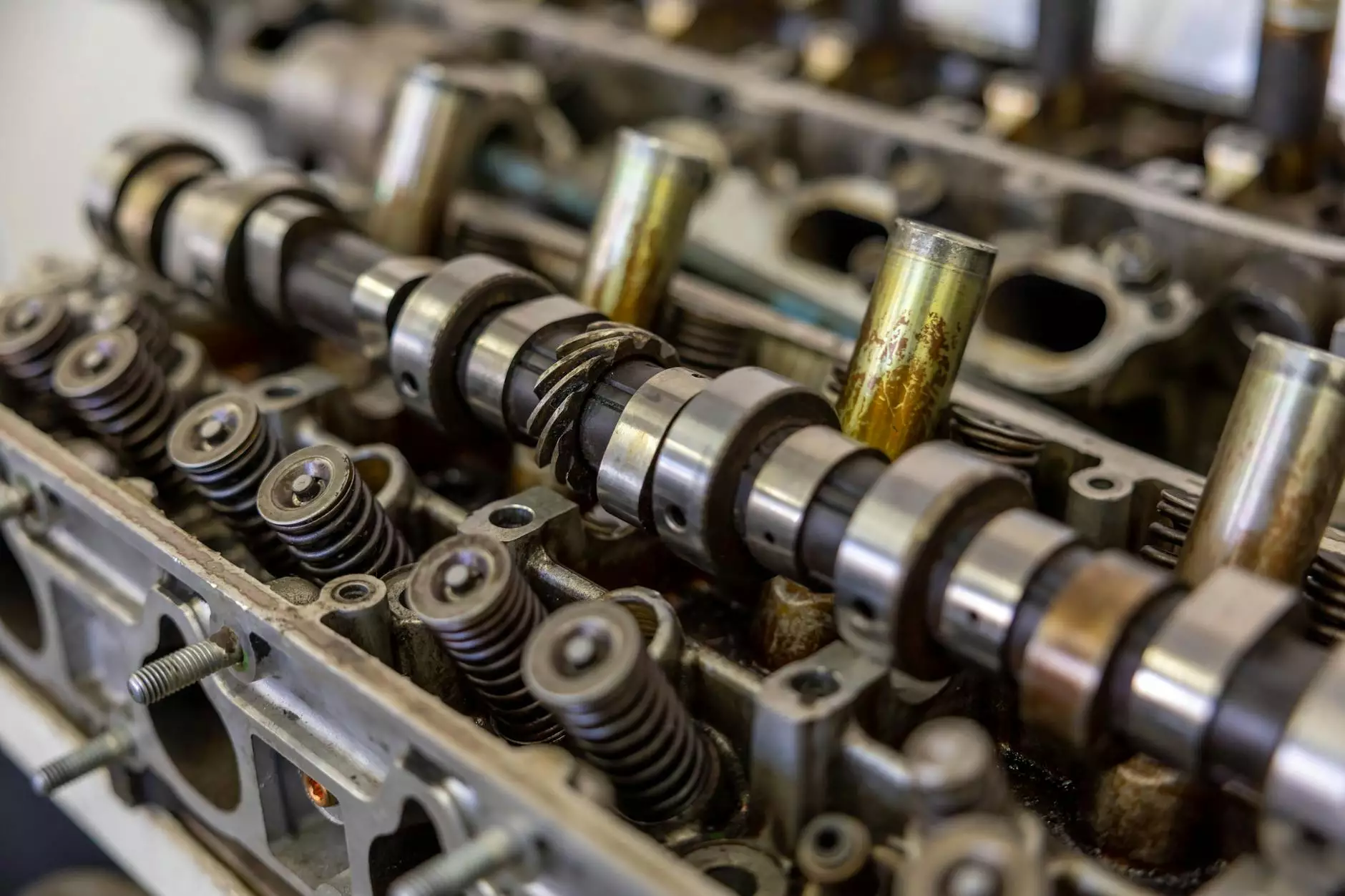

Understanding the Role of a **Large Crankshaft Manufacturer** in Diesel Engine Performance

In the realm of diesel engines, the crankshaft plays a pivotal role. As a core component that converts linear motion into rotational motion, the crankshaft is fundamental to the functioning of any diesel engine. Thus, the importance of a reliable and reputable large crankshaft manufacturer cannot be overstated. This article delves into everything you need to know about large crankshaft manufacturing, how to choose the right supplier, and the broader context of diesel engine parts and spare parts suppliers.

The Essential Functions of a Crankshaft

The crankshaft is designed to do much more than just spin. It must endure significant stresses and strains while facilitating seamless engine performance. Here are the primary functions of a crankshaft:

- Converting Motion: The crankshaft transforms the up-and-down motion of the pistons into a rotational motion that ultimately powers the wheels.

- Balancing Engine Forces: A well-made crankshaft helps balance the forces within the engine, significantly reducing vibrations.

- Fuel Efficiency: A quality crankshaft contributes to the overall efficiency of the engine by ensuring optimal fuel combustion and minimizing losses.

- Durability: Given its exposure to extreme conditions, the crankshaft must be durable to withstand physical wear and tear over extended periods.

Why Quality Matters: The Benefits of Choosing a High-End Large Crankshaft Manufacturer

When selecting a manufacturer for large crankshafts, quality is paramount. A high-end large crankshaft manufacturer guarantees several benefits, including:

- Enhanced Performance: Quality materials and engineering lead to better engine performance.

- Longevity: High-quality crankshafts are less likely to fail or require replacement, saving costs in the long run.

- Customization: Leading manufacturers offer customization options to meet specific engine requirements.

- Availability of Spare Parts: Reputable suppliers ensure that spare parts are readily available for repairs or replacements.

Understanding the Manufacturing Process of Crankshafts

The process of manufacturing crankshafts is complex and involves several key stages:

1. Material Selection

The choice of material is crucial. Manufacturers often use high-grade steel or iron alloys known for their tensile strength and durability.

2. Forging and Machining

The initial shaping of the crankshaft is achieved through forging, where raw metal is heated and shaped. Following this, precision machining ensures that all dimensions meet strict tolerances.

3. Heat Treatment

Heat treatment processes enhance the mechanical properties of the crankshaft, making it more resilient to fatigue and wear.

4. Surface Finishing

A proper surface finish reduces friction, improves lubrication, and contributes to the overall efficiency of the engine.

5. Quality Control

Leading manufacturers implement rigorous quality control measures, including stress tests and inspections, to ensure each crankshaft meets industry standards.

Choosing the Right Manufacturer for Your Needs

Selecting the right large crankshaft manufacturer is crucial for maintaining the reliability and performance of your diesel engines. Here are some tips:

- Research and Reputation: Look for manufacturers with a strong reputation in the industry. Check reviews and testimonials.

- Experience: Companies that have been in business for significant periods often possess more expertise in manufacturing quality parts.

- Certifications: Verify that the manufacturer holds relevant certifications, which reflect adherence to industry standards.

- After-Sales Support: A good manufacturer offers reliable after-sales support, including technical assistance and spare parts availability.

- Customization Capability: Consider whether the manufacturer can provide custom solutions tailored to your specific needs.

Exploring the Impact of Technology on Crankshaft Manufacturing

With technological advancements, crankshaft manufacturing has evolved significantly. Embracing new technologies leads to:

- Increased Precision: Modern manufacturing techniques ensure greater precision in producing crankshafts, resulting in enhanced performance.

- Automation: The integration of automation reduces labor costs and increases production efficiency.

- Innovative Materials: New materials are being developed to improve strength-to-weight ratios and resist environmental impacts.

- Advanced Testing: Technology enables rigorous testing methods to evaluate durability and performance before a product reaches the market.

The Role of Diesel Engine Parts and Spare Parts Suppliers

To ensure that engines run smoothly, quality diesel engine parts are indispensable. Alongside crankshafts, here are other critical components:

- Pistons: Essential for compressing fuel and air within the cylinder.

- Injectors: They play a vital role in delivering the right amount of fuel at the optimal time.

- Turbochargers: They enhance engine efficiency by forcing extra air into the combustion chamber.

- Oil Pumps: Maintain proper lubrication to minimize friction and wear.

Working with dependable spare parts suppliers ensures that businesses can quickly access replacements, minimizing downtime and maintaining productivity.

Conclusion: The Future of Crankshaft Manufacturing

As the demand for high-performance diesel engines continues to grow, the role of a large crankshaft manufacturer becomes increasingly critical. By investing in quality manufacturing, businesses can ensure the reliability and efficiency of their engine systems. Embracing technological innovations and maintaining robust supplier relationships will pave the way for continued success in the diesel engine parts industry. At client-diesel.com, we pride ourselves on being a trusted source for high-quality large crankshafts and other diesel engine components, dedicated to excellence and customer satisfaction.

Call to Action

Ready to optimize your diesel engine performance? Contact us today at client-diesel.com and discover how our premium large crankshafts can drive your success forward!